|

Our Products

|

Mineral Processing System |

|

We are manufacturer and exporter of Mineral Processing System,Manufacturer of Mineral Processing System,Supplier of Mineral Processing System,Mineral Processing System in India, Exporters of Mineral Processing System

|

| Comminution Comminution is the process in which solid materials are reduced in size, encompassing crushing, grinding and other techniques. It is an important operation in mineral processing, the ceramic industry, the electronics industry and other fields. Within industrial uses, the purpose of comminution is to reduce the size and to increase the surface area of solids. It is also used to free useful materials from matrix materials in which they are embedded, and to concentrate minerals.It constitute a significant proportion of capital and operating costs in mineral processing plants and is critical to the economic performance of most mining operations. CrushingCrushing process is reducing rock into smaller chunks. it is a very complex process. The following factors will influence the crushing ratio. They are material resistance strength, hardness,toughness, shape, size, humidity, density, homogeneity, and external conditions, such as the instantaneous interaction and distribution of materials at the moment of crushing. All these factors make the process of breaking complicated, and so far a unified and complete set of theortical is not achieved to demonstrate the crushing ratio.Crushing and sizing equipments are available for surface, under installation or mobile application, and for climatic conditions that range from tropical to arctic. Crushing Products - Gyratory Crushers

- Cone Crushers

- Low Speed Sizers

- Roll Crushers

- Jaw Crushers

- Feeder-Breakers

- Hammermills

- Vertical Shaft Impactors

- Shaft rotary shear shredder

GrindingProud to have 25 years of experience in the size reduction industry with several grinding mill installations and super-talented personnel, who understand the challenges in mineral processing and provide the best solutions. Star Trace has the people, technology, expertise, and product support services to help you maximize the efficiency of your grinding circuit. Our knowledge will help you make your work unique and reliable. Star Trace provides quality equipment and services necessary to maximize the return on your grinding equipment investment. We work with you from initial conception through the life of the project. “We have established ourselves in many countries where our products are being used. We are committed to provide extra-ordinary service to our customers with a strong local presence. Our vision is to be recognized worldwide as a supplier of superior quality products and services with on-time delivery and unmatched value. Our strong grip on mining, industrial minerals, and power industries has resulted in a complete line of grinding mills and systems for wet and dry processing of metallic and non-metallic materials. Grinding productsOur standard line of equipment for wet and dry grinding systems include complete range of: - Ball Mills

- Pebble Mills

- Rod Mills

- Vertical Mills

- Vibrating Mills

KeyWord Tag:

Comminutions , Comminution ,Manufacturer of Comminution , Supplier of Comminution , Comminution in India, Exporters of Comminution , Comminution manufacturers, Comminution suppliers, Comminution exporters, Comminution manufacturing companies, Comminution in Chennai, Comminution supplier in India, Laterite Comminution in Chennai, Laterite Comminution manufacturer in India, Comminution India , Laterite Comminution manufacturers in India, Indian manufacturers of Comminution , Comminution Indian supplier, |

Send Enquiry Mineral Processing System

| Mineral Processing System

Classification:Minerals can be classified into several types based on their properties such as hardness, specific gravity, color, luster, streak, cleavage, sizing and crystal form.(Mineral Processing System) Particles are produced with a continuous size distribution from the coarsest particle in the product to the finest particle (which is theoretically a particle of zero size), when rocks are broken by blasting, crushing or grinding. The continuity of the particle size distribution is broken when the fragmented material is subjected to an imposed process such as sizing or concentration. Any products of the process have their own unique size distribution different from that of the original material.(Mineral Processing System) Sizing:Sizing is the general term for separation of particles according to their size.(Mineral Processing System) The simplest sizing process is screening or passing the particles to be sized through single screen or number of screens.(Mineral Processing System) Screening equipment can include grizzlies, bar screens, wedge wire screens, banana screens, multi deck screens, vibratory screens, fine screens, flip flop screens and wire mesh screens. Screens can be static (typically the case for very coarse material), or they can incorporate mechanisms to shake or vibrate the screen. The process is performed based on some considerations including the screen material, the aperture size, shape and orientation, the amount of near sized particles, the addition of water, the amplitude and frequency of the vibrations, the angle of inclination, the presence of harmful materials, like steel and wood, and the size distribution of the particles. Classification refers to sizing operations that exploit the differences in settling velocities exhibited by the particles of different size.(Mineral Processing System) Classification equipment includes ore sorters, gas cyclones, hydrocyclones, rotating trommels, rake classifiers or fluidized classifiers. Particle size analysis refers to the determination of the particle size distribution of the materials to be processed, which is an important factor in both communication and sizing operations. Many techniques for analyzing particle size are used, and the techniques include both off-line analyses which require that a sample of the material be taken for analysis, and on-line techniques that allow for analysis of the material as it flows through the process. This process can be achieved by the following machineries: - Vibro Screen Rectangular(Mineral Processing System)

- Gyratory Screen

- Linear Motion Horizontal Screen

- Grizzly Screen(Mineral Processing System)

- Circular Motion Inclined Screen

- Vibrating Shifter(Mineral Processing System)

- Vibrating Tumbler Screening Machine

- Banna Screen(Mineral Processing System)

- Flip Flop Screen

- Sieve Bend (single and double)

- Screw Classifier(Mineral Processing System)

- Micro Sieve Shaker

- Dry and Wet Sieve Shaker

KeyWord Tag:Mineral Processing System,Mineral Processing Systems,Manufacturer of Mineral Processing Systems, Supplier of Plate Magnet,Mineral Processing Systemsin India, Exporters of Mineral Processing Systems,Mineral Processing Systemsmanufacturers,Mineral Processing Systemssuppliers,Mineral Processing Systemexporters,Mineral Processing Systemsmanufacturing companies,Mineral Processing Systemsin Chennai,Mineral Processing Systemssupplier in India,Mineral Processing Systemin Chennai, Mineral Processing Systemsmanufacturer in India,Mineral Processing SystemsIndia ,Mineral Processing Systemsmanufacturers in India, Indian manufacturers of Mineral Processing Systems,Mineral Processing SystemIndian supplier,

|

Send Enquiry

| Electrostatic separation:The electrostatic separators are classified into two main types, such as electrodynamic separators or high tension roll separators and electrostatic plate and screen separators. Both the separators work in similar ways, but the forces applied to the particles are different i. E. Gravity and electrostatic attraction forces. In high tension rollers, the particles that subsequently travel on a drum are charged by a corona discharge. The conducting particles lose their charge to the drum and are removed from the drum with centripetal acceleration. The electrostatic plate separators work by passing a stream of particles past a charged anode. The conductors lose electrons to the plate and are pulled away from the other particles due to the induced attraction to the anode. These separators are used for particles between 75 and 250 micron and for efficient separation to occur, where the particles need to be dry, and have a close size distribution and uniform in shape. Of these considerations, one of the most important is the water content of the particles. This is important as a layer of moisture on the particles renders the non-conductors as conductors as the layer of the water is conductive. Electrostatic plate separators are usually used for streams that have small conductors and coarse non-conductors. The high tension rollers are usually used for streams that have coarse conductors and fine non-conductors. The plate separators used for separating mineral sands ie. Zircon, rutile and ilmenite are separated from the silica gangue. The separation is performed in a number of stages with roughers, cleaners, scavengers and recleaners. Application: - Beneficiation of ferrous, non -ferrous and rare metal ones.

- Recovery of metals from industrial wastes (electronic or electrical

- Engineering scrap, cables etc.

- Recovery of dielectric materials (e. G. Plastics) for recycling.

- Purification of metal and non -metal powders.

- Separation of industrial minerals (quarts, feldspar, mica etc. ).

- Shape and size classification.

This process can be achieved by the following our range of machineries: - High tension roll separator

- Late and screen electrostatic separators

- Tribostatic separator

keyword tag:

Electrostatic separation, electrostatic separations, manufacturer of electrostatic separations, manufacturer of electrostatic separation, supplier of electrostatic separation, electrostatic separation in India, exporters of electrostatic separation, electrostatic separation manufacturers, electrostatic separation suppliers, electrostatic separation exporters, electrostatic separation and manufacturing companies. |

Send Enquiry

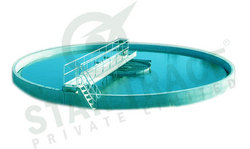

| Sedimentation :Sedimentation is a process water treatment generally follows a step of chemical coagulation and flocculation, which allows grouping particles together into flocs of a bigger size. This increases the settling speed of suspended solids and allows settling colloids. Sedimentation is often used as a primary stage in modern waste water treatment plant, reducing the content of suspended solids as well as the pollutant embedded in the suspended solids. Due to the large amount of reagent necessary to treat wastewater, preliminary chemical coagulation and flocculation are generally not used, remaining suspended solids being reduced by following stages of the system. However, coagulation and flocculation can be used for building a compact treatment plant, or for further polishing of the treated water. In the Activated Sludge treatment process, flocs being created through biological activity are collected in sedimentation tanks, generally referred to as Secondary Clarifiers or Secondary Sedimentation Tanks. Sedimentation tanks can be of different shapes, often rectangular or circular. They are sized in order to have an optimal sedimentation speed. If sedimentation speed is too high, most particles will not have sufficient time to settle, and will be carried with the treated water. If the speed is too low, the tanks will be of an excessive size. As turbulence is a damaging factor leading settled particles to go back in suspension, several devices are used to ensure a quiet flow, such as carefully designed water inlet with baffles. Sedimentation be made more efficient by the use of stacks of flat pieces that slope slightly upwards in the direction of flow, called special separators. They are parallel and separated by a small distance. These structures work in two ways: - They provide a very large surface area onto which particles may fall and become stabilized.

- Because flow is temporarily accelerated between the plates and then immediately slows down, this helps to aggregate very fine particles that can settle as the flow exits the plates.

The use of these separators may allow the use of a smaller sedimentation tank and may enable finer particles to be separated. Typically such structures are used for difficult-to-treat waters, especially those containing colloidal materials. Sedimentation Products : - Clarifiers

- Thickeners

- Spiral Clarifiers

KeyWord Tag:Sedimentations , Sedimentation ,Manufacturer of Sedimentation , Supplier of Sedimentation, Sedimentation in India, Exporters of Sedimentation , Sedimentation manufacturers, Sedimentation suppliers, Sedimentation exporters, Sedimentation manufacturing companies, Sedimentation in Chennai, Sedimentation supplier in India, Sedimentation in Chennai, Sedimentation manufacturer in India, Sedimentation India ,Sedimentation manufacturers in India, Indian manufacturers of Sedimentation , Sedimentation Indian supplier, |

Send Enquiry Filtration And Dewatering System

| Filtration :Filtration is commonly the mechanical or physical operation which is used for the separation of solids from fluids (liquids or gases) by interposing a medium through which only the fluid can pass. Oversize solids in the fluid are retained, but the separation is not complete; solids will be contaminated with some fluid and filtrate will contain fine particles (depending on the pore size and filter thickness). Filtration is also used to describe some biological processes, especially in water treatment and sewage treatment in which undesirable constituents are removed by adsorption into a biological film grown on or in the filter medium. There are many different methods of filtration; all aim to attain the separation of substances. Separation is achieved by some form of interaction between the substance or objects to be removed and the filter. The substance that is to pass through the filter must be a fluid, i.e. a liquid or gas. Methods of filtration vary depending on the location of the targeted material, i.e. whether it is dissolved in the fluid phase or suspended as a solid. Two main types of filter media are employed - surface filter, a solid sieve which traps the solid particles, with or without the aid of filter paper (e.g. Belt filter, Rotary vacuum-drum filter, Crossflow filters, Screen filter), and a depth filter, a bed of granular material which retains the solid particles as it passes (e.g. sand filter). The first type allows the solid particles, i.e. the residue, to be collected intact; the second type does not permit this. However, the second type is less prone to clogging due to the greater surface area where the particles can be trapped. Also, when the solid particles are very fine, it is often cheaper and easier to discard the contaminated granules than to clean the solid sieve. Filter media can be cleaned by rinsing with solvents or detergents. Alternatively, in engineering applications, such as swimming pool water treatment plants, they may be cleaned by backwashing. Self-cleaning screen filters utilize point-of-suction backwashing to clean the screen without interrupting system flow. Filtration Equipments: Vacuum Filtration Unit: - Filter Presses

- Vertical Pressure

- Beltpress Filters

- Granular Media Filters

Pressure Filtration Unit: - Filter Presses

- Vertical Pressure

- Beltpress Filters

- Granular Media Filters

Dewatering :De-watering is an important process in mineral processing. The purpose of dewatering is to remove water contained in particles. This is done for a number of reasons, specifically, to enable ore handling and concentrates to be transported easily, allow further processing to occur and to dispose of the gangue. KeyWord Tag:Filtration And De-watering System,Filtration And De-watering Systems,Manufacturer of Filtration And De-watering System, Supplier of Filtration And De-watering System,Filtration And De-watering System in India, Exporters of Filtration And De-watering System,Filtration And De-watering System manufacturers,Filtration And Dewatering Systemsuppliers,Filtration And Dewatering System exporters,Filtration And Dewatering System manufacturing companies,Filtration And Dewatering Systemin Chennai,Filtration And Dewatering Systemsupplier in India,Filtration And De-watering Systemin Chennai,Filtration And Dewatering Systemmanufacturer in India,Filtration And Dewatering SystemIndia ,Filtration And Dewatering System manufacturers in India, Indian manufacturers of Filtration And Dewatering System,Filtration And Dewatering SystemIndian supplier. |

Send Enquiry

| Customer Services :Star trace is your single source for spare parts, service, maintenance, asset management, and operational services. Our customer services provide a wide range of services for mineral processing equipment and systems including raw material testing, process design, equipment installation, troubleshooting, process and mechanical analysis, and commissioning of new plants. Futhur to that we have designed and installed your processing system, we do everything possible to provide the tools to ensure that those systems continue to operate at optimum levels at all times. Technical Services : - Erection & Commissioning

- Operation & Maintenance

- Expert Services

- Technical Assistance

- Training

Operation & Maintenance : - Plant management

- Plant maintenance

- Asset Management

Rebuilds & Modernizations :Star Trace can rebuild your equipment or provide the most current state-of-the-art equipment improvements and/or system upgrades for operational efficiency and enhanced functionality. Quality & Reliable OEM Parts Contact our trained service personnel to get authentic, high quality, original . equipment manufacturer (OEM) spare and replacement parts. Test Facility :Research and Development (R&D) has always been an important part of Star Tarce operations. We offer analysis of a broad range of materials and processes, and can conduct pilot plant feasibility studies ranging from Comminution, Classification, Megnetic Separation, Electrostatic Separation, Flotation, Material Handling, Sedimentation, Filtration, Dewatering, Pyroprocessing and Precious metals Recovery . We also have the capability and expertise to design your pilot plant, build it, and optimize it for profitability.

Products : - Product Review & Improvement

- Repair

- Original OEM Spares

- Retrofits

- Ufe Cycle Analysis

Metallurgical Testing : - Ore physical / chemical testing

- Ore Amenability Testing

- Process Development

- Flowsheet Layout

- Plant Design

Engineering Services : - Process Audits

- Equipment Audits

- Erection Supervision

- Testing

- Detailed Engineering

- Training

KeyWord tag:

Service , Services ,Manufacturer of Services , Supplier of Services, Services in India, Exporters of Services , Services manufacturers, Services suppliers, Services exporters, Services manufacturing companies, Services in Chennai, Services supplier in India, Services in Chennai, Services manufacturer in India, Services India ,Services manufacturers in India, Indian manufacturers of Services , Services Indian supplier, |

Send Enquiry

| Projects :The equipment provided by Star trace becomes part of a system, without exception. The system may be a wet / dry grinding circuit or a complete iron ore concentration plant with a pelletizing system or etc. Star trace always has the capability to provide a complete system to our customers on turnkey basis. An Optimized Plant The system turns an ore, mineral or waste material from one stage into a value added product in one, two or more stages later. The way it is done determines how well optimized a plant is. We start from the creation of a process flowsheet. Key parts of the design may be tested in one of the Star trace testing center to verify equipment specifications. The final flowsheet will provide the lowest total cost of operation with maximum recovery and utilisation with minimum space and investment addwith dully giving important socioeconomic considerations. Technical ExpertiseStar trace has equipment design experience of more than 25 years. In designing a system, we include this expertise, combine it, and create a unique and best individual part. Star trace’s engineers are recognized as experts in their fields. Process GuaranteeStar trace is recognized for its excellence in keeping promises. To our customers, it means there is never a question of who is responsible, or a question of one vendor pointing at another if there is an interface problem. Process guarantees are valid across all of the equipment supplied by Star trace whether it is our proprietary equipment or from a third party.

Financing and Other Services Star Trace can assist in obtaining financing for a project through internal and external sources. Other services we provide include process reviews, process upgrades, process automation implementation and maintenance evaluations. These and future care service are part of Star Trace providing the complete system. Aftersales: Star Trace has drawings, specifications, manuals and design calculations for the mineral processing equipment previously sold.These product ranges include Grinding Mills, Process Equipment, Slurry Handling, Pyro Systems and Bulk Material Handling Systems. Spare PartsStar Trace can provide spare and wear parts to the correct specifications for all the equipment while incorporating with the latest design. It reduces down time of the production considerably. Site ServicesStar Trace had experienced and safety certified engineers for site services, As listed below : - Installation and commissioning

- Routine and preventive maintenance

- Operation and maintenance training

- Mechanical and Process Audits

- Emergency repairs

- Troubleshooting

RefurbishingStar Trace will repair and refurbish services for following equipments - Special Lining

- Vibrating Screen

- Electro Magnets

- Permanent Magnets

- Mill bearings

- Drive systems

- Flotation mechanisms

KeyWord Tag: Projects And Aftersale, Projects And Aftersales,Manufacturer of Projects And Aftersales, Supplier of Projects And Aftersaless, Projects And Aftersales in India, Exporters of Projects And Aftersales, Projects And Aftersalesmanufacturers, Projects And Aftersalessuppliers, Projects And Aftersalesexporters, Projects And Aftersales manufacturing companies, Projects And Aftersalesin Chennai, Projects And Aftersalessupplier in India, Projects And Aftersales in Chennai, Projects And Aftersalesmanufacturer in India, Projects And AftersalesIndia ,Projects And Aftersalesmanufacturers in India, Indian manufacturers of Projects And Aftersales, Projects And Aftersales Indian supplier, |

Send Enquiry

|